|

|

Teramoto Koji

|

Research field 【 display / non-display 】

-

Manufacturing Technology (Mechanical Engineering, Electrical and Electronic Engineering, Chemical Engineering) / Manufacturing and production engineering

Keywords for Research Field 【 display / non-display 】

-

Manufacturing System

-

Machining

Research themes 【 display / non-display 】

-

Workholding in machining operation

low rigidity,modelling,monitoring,2013.04 ~ 2019.03

Graduate school・Graduate course, etc. 【 display / non-display 】

-

Osaka University

1993,Master's program,Graduate School, Division of Engineering,Deparment of Computer controlled machinery,Completed,Japan

Graduate school・major, etc. 【 display / non-display 】

-

Osaka University

1991,Faculty of Engineering,Department of Mechanical Engineering,Graduate,Japan

Degree 【 display / non-display 】

-

Doctor of Engineering

機械加工における適応的作業遂行のための技能拡張に関する研究

Academic Society 【 display / non-display 】

-

The Japan Society for Precision Engineering

-

The Japan Society of Mechanical Engineers

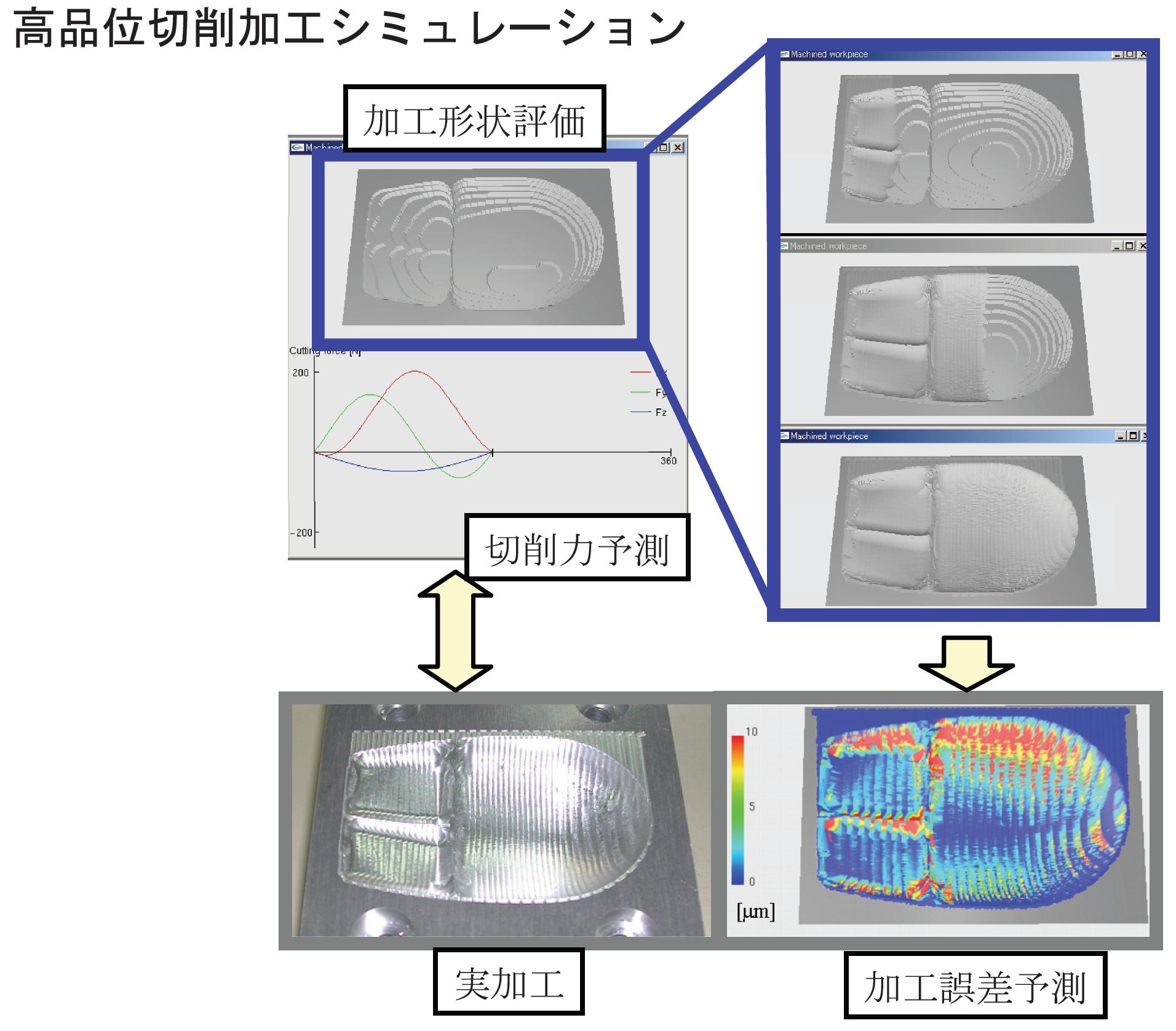

切削加工現場へのデジタル化技術の適用

Purpose of Research

シミュレーションで切削加工の職人技をサポートする複雑な切削加工においては高度な職人の技術が必要不可欠だが、現在その職人が後継者不足などの理由により減少している。そのような社会の動向に合わせて、切削加工シミュレーションなどの情報技術を新たな道具として活用する次世代のものづくり環境を提案する。

Summary of Research

デジタル加工・生産技術と人間特性の双方を加味するシミュレーションやCAD/CAMなどの情報システムと実際の加工現場は、限られた条件下でしか連携できない。この研究では加工プロセスのデジタル化を基にした生産技術と、個別の作業現場や作業者の人間特性を考慮した加工・生産システム設計の融合を試みる。

Features / Benefits of Research

| 1.Point of research | 2.Research of novelty |

|---|---|

|

|

| 3.Primacy of Technology | 4.Situation of patent-related |

|

|

Books 【 display / non-display 】

-

Ascience of skills( in Japanese)

岩田一明・小野里雅彦・橋詰謙・松尾知之・吉川恒夫・馬野元秀・椹木哲夫・野村幸正・入来篤史・寺本孝司・高谷裕浩,国際高等研究所学術出版,スキル研究の系譜,(p.208),2007.07

Papers 【 display / non-display 】

-

工作物剛性の低下を伴うエンドミル加工における工作物変形挙動のモデル化

寺本 孝司, 中尾 祐大朗, 日比野 悠椰,日本機械学会論文集,vol.89,(928),2023.12

-

Statistical model comparison based on variation parameters for monitoring thermal deformation of workpiece in end-milling

Mengmeng Yang, Feng Zhang, and Koji Teramoto,International Journal of Advcanced Manufacturing Technology,2023.09

-

Statistics-Based Measuring Point Selection for Monitoring the Thermal Deformation of a Workpiece in End-Milling

Mengmeng Yang, Feng Zhang, and Koji Teramoto, International Journal of Automation Technology,vol.16,(5),(p.562 ~ 571),2022.09

-

On-machine Estimation of Workholding State for Thin-walled Parts

Zeng, Jingkai, Teramoto, Koji, Matsumoto, Hiroki,International Journal of Automation Technology,vol.15,(6),(p.860 ~ 867),2021.11

-

Statistical Modelling of Machining Error for Model-based Elastomer End-milling

Chainawakul, Adirake, Teramoto, Koji, Matsumoto, Hiroki,International Journal of Automation Technology,vol.15,(6),(p.852 ~ 859),2021.11

International conference proceedings 【 display / non-display 】

-

Research on estimation of clamping force decrease due to workpiece rigidity reduction in machining

Shunya TAGUCHI, Koji TERAMOTO, Naruki SHOJI,Proc. of the 27th International Conference on Mechatronics Technology,2024.11

-

Research on measuring point selection for strainbased on-machine estimation of workholding states

Yu YAN, Koji TERAMOTO, Naruki SHOJI and Hiroki MATSUMOTO,Proc. of the 20th International Conference of Precision Engineering,Article Number:OS05-02,2024.10,Sendai

-

Research on Measuring Point Selection for Workpiece Thermal Monitoring

Mengmeng YANG, Koji TERAMOTO, Feng ZHANG,Proc. of The 10th Int. Conf. on Leading Edge Manufacturing in 21st Century,2021.11

-

Modelling of fixturing force reduction caused by workpiece rigidity change

Yuya HIBINO and Koji TERAMOTO,Proc. of The 10th Int. Conf. on Leading Edge Manufacturing in 21st Century,2021.11

-

Proposal of a Framework for Empirical Modelling of Complex Machining Phenomena

Adirake Chainawaku, Koji Teramoto, Zejian Wu, Takahiro Katsube,Proc of 18th International Conference on Precision Engineering,Article Number: B-1-2,JSPE,2020.11,Virtual

Editorial and Commentary 【 display / non-display 】

Research reports 【 display / non-display 】

-

タイ王国チェンマイ大学との学術国際交流について(合同シンポジウムの活動を中心に)

風間 俊治, 花島 直彦, 湯浅 友典, 寺本 孝司, 藤木 裕行, 長船 康裕, 松本 大樹, 河合 秀樹,室蘭工業大学紀要,vol.70,(p.33 ~ 55),2021.03

-

A Framework of Accuracy Assured Machining for Smart Manufacturing

Koji TERAMOTO , Dongjin WU, Kentaro OTA and Ryota HAYASHI,Memoirs of the Muroran Institute of Technology,vol.65,(p.35 ~ 39),2016.03

-

Experimental investigation of machining error in elastomer endmilling

Koji TERAMOTO and Kazuhisa YABUKI,室蘭工業大学紀要,vol.62,(p.55 ~ 58),2013.03

Presentaion at conference, meeting, etc. 【 display / non-display 】

-

切削加工における工作物剛性低下による把持力減少量推定に関する研究

田口峻也,寺本孝司,荘司成熙,日本設計工学会 2024年度 秋季大会研究発表講演会,日本設計工学会,日本設計工学会 2024年度 秋季大会研究発表講演会講演論文集,2024.09.21,北海道,Japan

-

能動義手のハーネスレス化のためのケーブルシステムに関する研究

原田 樹,寺本孝司,荘司成熙,2024年度精密工学会秋季大会学術講演会,精密工学会,2024年度精密工学会秋季大会学術講演会講演論文集,2024.09.04,岡山,Japan

-

切削工具機上計測情報を反映した個別切削シミュレーションによる切削力推定

木村陸人,寺本孝司,荘司成熙,2024年度精密工学会秋季大会学術講演会,精密工学会,2024年度精密工学会秋季大会学術講演会講演論文集,2024.09.04,岡山,Japan

-

Comparison of estimation accuracy at different measuring point sets for strain-based on-machine estimation of workholding statees

Yan Yu,Koji Teramoto,令和5年度 精密工学会 北海道支部 学術講演会,精密工学会北海道支部,令和5年度 精密工学会 北海道支部 学術講演会講演論文集,(p.31-32),2023.08.26,北海道,Japan

-

能動多指ハンドの組立性改善に関する研究

原田 樹,寺本 孝司,令和5年度 精密工学会 北海道支部 学術講演会,精密工学会北海道支部,令和5年度 精密工学会 北海道支部 学術講演会講演論文集,(p.67-68),2023.08.26,北海道,Japan

Class subject in charge 【 display / non-display 】

-

フレッシュマンセミナー(前半8週)

2025,Department

-

機械工作法実習(夜間)

2025,Department

-

機械工作法実習(週2回開講)

2025,Department

-

(前半8週)フレッシュマンセミナー(Aクラス)

2025,Department

-

機械工作法実習(週2回開講)

2024,Department